Taurion 800/1100

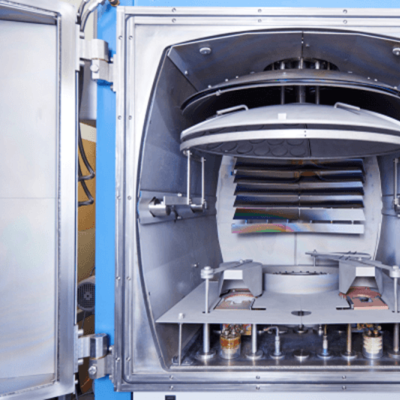

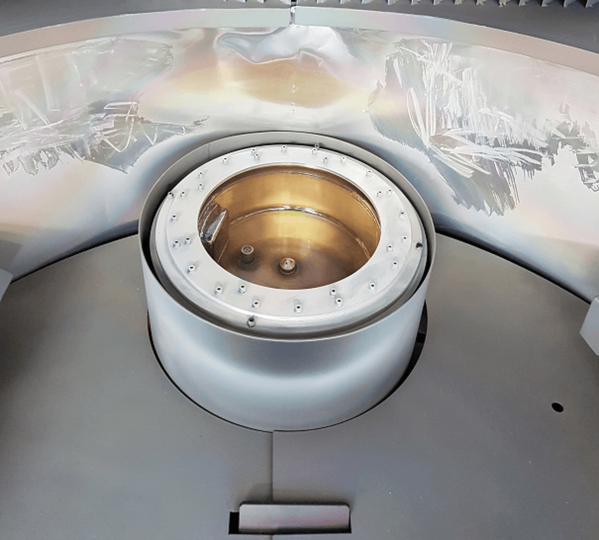

Is a fully automatic, cubic, RF-plasma enhanced evaporation batch coating system with a calotte diameter of 800/1100 mm for RFPE-PVD processes.

The high vacuum evaporation system includes a filament free and low maintenance RF plasma source with 122 mm and 265 mm exit diameter.

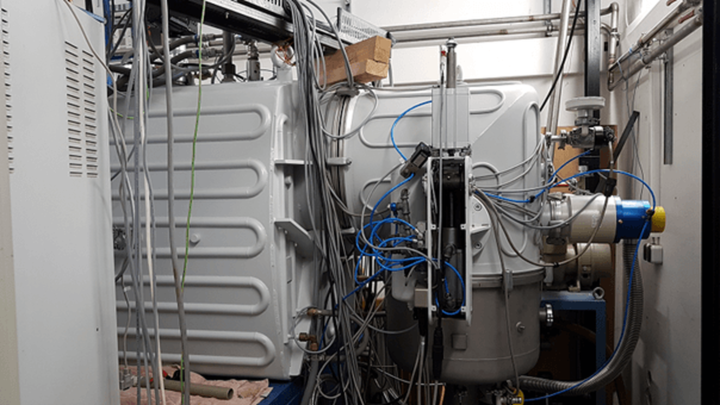

The basic TAURION 800/1100 system consists of a water heated/cooled chamber and door including rotary drive, water battery on frame and power rack. The fully automatic PC control ensures an operator friendly handling. The system can be equipped with either cryo- or oil diffusion high vacuum pump and a standard or dry forevacuum pump set including vacuum pressure monitoring.

* Images are enlarged when clicked

Application examples

- ITO-Indium Tin Oxide – Semiconductor Application

Would you like more information?

Then download the product data sheet now or

get in touch with us!

Our service and customised solutions

-

Upgrading and development

-

Systems and process control

-

Maintenance

Our equipment variants for our coating systems

-

Various pump systems

(Dry, Turbo, Kyro and Oil Diffusion) -

Ion sources

-

E-beam source