PRO 500 - 1100

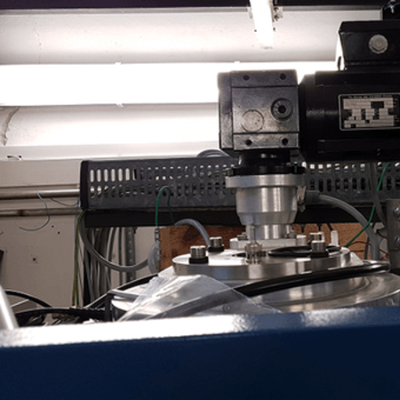

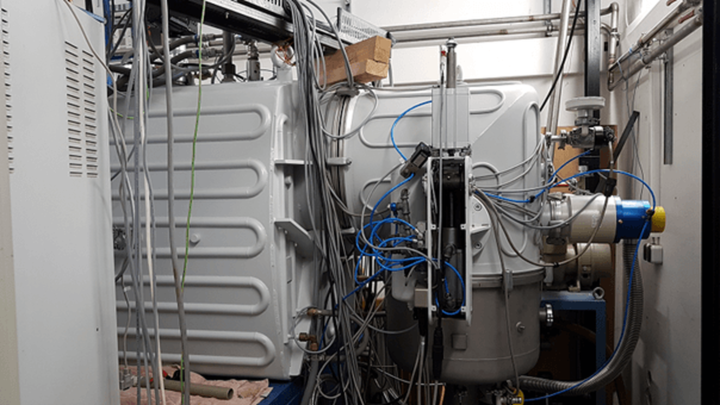

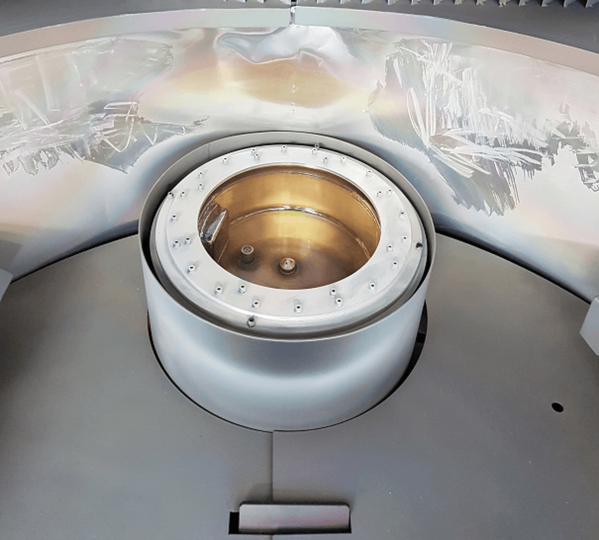

The PRO500/1100 high vacuum PVD coating system is PROVAC’s solution for flexible evaporation techniques in the fields of semiconductor, precision optics and ophthalmic industry.

Integration of the most sophisticated and time-tested instruments and components by industrial leaders allows the production of thin film coatings on various materials using a wide range of coating materials.

Advanced yet simplified software designed to satisfy the most demanding process engineer, and yet still provide a very user friendly interface for the beginning technician.

Complete process automation, remote control, trending, data analysis and recovery. The system is best suited for laboratory and pilot production of single and multilayer, metallic and dielectric coatings.

* Images are enlarged when clicked

Application examples

- III-V/ Compound

- Lift-off metallization

- Precision optics

Would you like more information?

Then download the product data sheet now or

get in touch with us!

Our service and customised solutions

-

Upgrading and development

-

Systems and process control

-

Maintenance

Our equipment variants for our coating systems

-

Various pump systems

(Dry, Turbo, Kyro and Oil Diffusion) -

Ion sources

-

E-beam source